What is a Flocculant? Its application in mining industry

In industrial processes—particularly in the mining sector—one of the greatest challenges is the separation of fine solid particles from liquids. These particles, generated during various stages such as grinding, flotation, and washing, can reduce the quality of recycled water and impair equipment efficiency. In this context, flocculants play a critical role as key chemical agents that facilitate and accelerate the sedimentation of suspended solids.

What is a Flocculant?

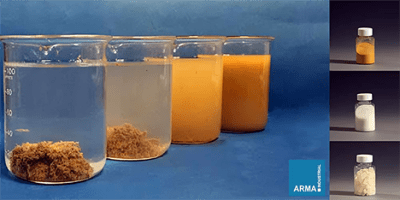

Flocculants are synthetic or natural polymers that create bonds between suspended particles, leading to the formation of aggregates or flocs. These flocs settle easily and can be separated from water. Flocculants are typically used alongside coagulants to enhance performance and are widely applied in water treatment, sludge dewatering, and mineral slurry clarification.

These compounds are commonly categorized into anionic, cationic, and nonionic types, and they work by neutralizing surface charges or bridging suspended particles, thereby enabling more effective aggregation and sedimentation.

Types of Flocculants

Flocculants are generally classified into three main categories based on the electric charge of their polymer chains:

- Anionic Flocculants – Suitable for particles with a positive charge, such as silica and metal oxides.

- Cationic Flocculants – Effective for separating negatively charged particles like organic matter, sludge, and certain minerals.

- Nonionic Flocculants – Electrically neutral and ideal for specific applications where pH sensitivity is critical.

Why Are Flocculants Important in the Mining Industry?

In mining operations, following ore extraction, several downstream processes such as grinding, gravity separation, flotation, and leaching are performed. These operations generate a large amount of suspended fine particles in water. If not efficiently separated, they can lead to the following problems:

- Reduced equipment efficiency

- Increased water consumption

- Elevated environmental pollution

Flocculant

In such conditions, flocculants play a vital role in optimizing water consumption and enhancing the efficiency of mineral processing operations.

This is where flocculants emerge as a key factor in improving water management and maximizing process performance in the mining industry.

Key Applications of Flocculants in Mining

- Accelerating the sedimentation of fine particles in thickeners and settling ponds

- Increasing the clarity of recycled water for reuse

- Reducing wastewater contamination and improving treatment efficiency

- Enhancing the performance of filter press and centrifuge systems

- Lowering operational costs and improving sludge and slurry management

Advantages of Using Flocculants in Mineral Processing

- Reduces raw water consumption and enables recovery of over 90% of process water

- Increases thickener capacity and reduces final sludge volume

- Improves the quality of return water and minimizes environmental pollution

- Saves energy by streamlining solid-liquid separation

- Extends equipment lifespan and lowers maintenance costs

| Mine Type | Application of Flocculant |

| Copper Mines | Sedimentation of flotation slurry |

| Iron Ore Mines | Clarification of magnetic separation wastewater |

| Coal Mines | Dewatering of coal tailings |

| Gold Mines | Settling of leaching tailings |

| Phosphate Mines | Enhancing performance of acid thickeners |

For more information, please contact the technical experts at Ayandeh Roshan Maghate Alyazhi Industrial Group (ArmaChemical).